For us, sustainable business means finding the best balance of human, environmental and commercial considerations. We see this as a continuous process aimed at demonstrating social responsibility, reducing our environmental impact and growing sustainably.

Sustainable packaging concept

Introducing innovative, biodegradable, and recycled materials for a greener future

This change is hard to miss. A new sustainable packaging concept has replaced our standard packaging for all three series in the range. Not only does the packaging look and feel good, it’s also certified.

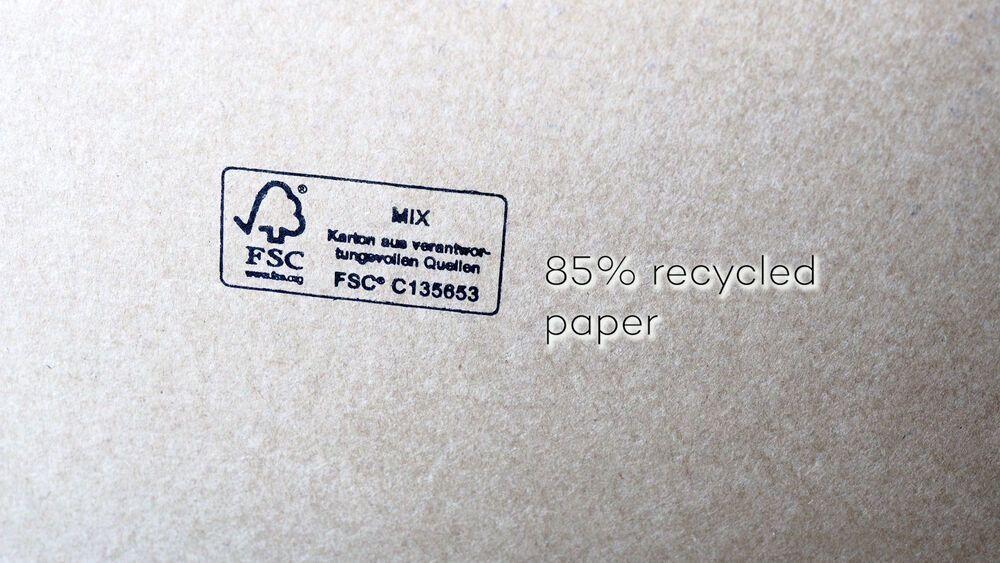

The packaging box is made from FSC Mix-certified corrugated cardboard, which is known for its sturdiness. At least 85% of the cardboard is made from recycled waste paper and only a small amount of energy is required for its manufacture.

For our packaging we use corn, wheat or potato starch-based glue, or a combination of the three. Starch glue has a low viscosity but can still be applied evenly over the entire width of the corrugating machine with modern gluing units. Ergo, less is more.

When it comes to sustainability, we work with certified partners and certified materials. In the future, all our suppliers and service providers will have to be on board with our environmentally friendly packaging concept ➞ we are investing in it.

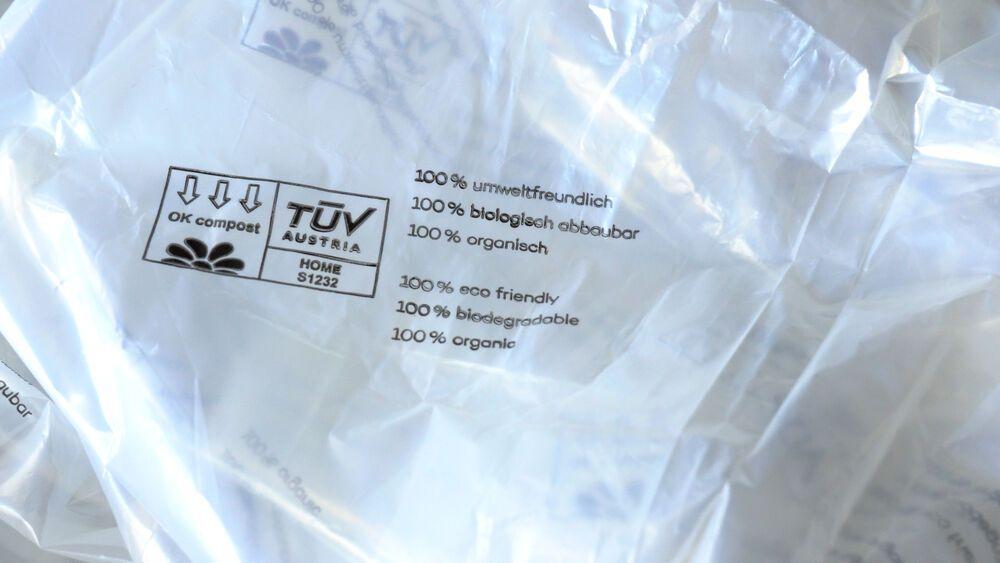

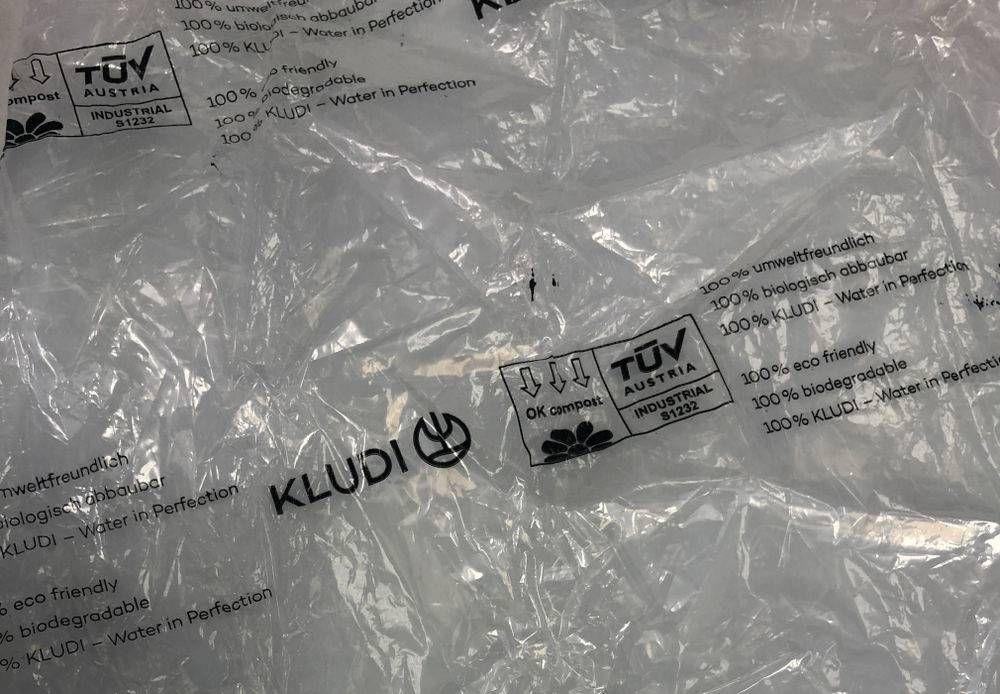

In line with our aspiration for plastic-free packaging, we are now using ecological bags. Although they look like plastic, they are actually made of renewable raw materials and are biodegradable. These new bags are made of cornstarch, which is obtained from the residual material leftover from food production, e.g., potato skins.

To make the packaging easier to recycle and thus even more environmentally friendly, we have scaled back to use just a single-colour print process with water-based ink instead of environmentally harmful UV colour.

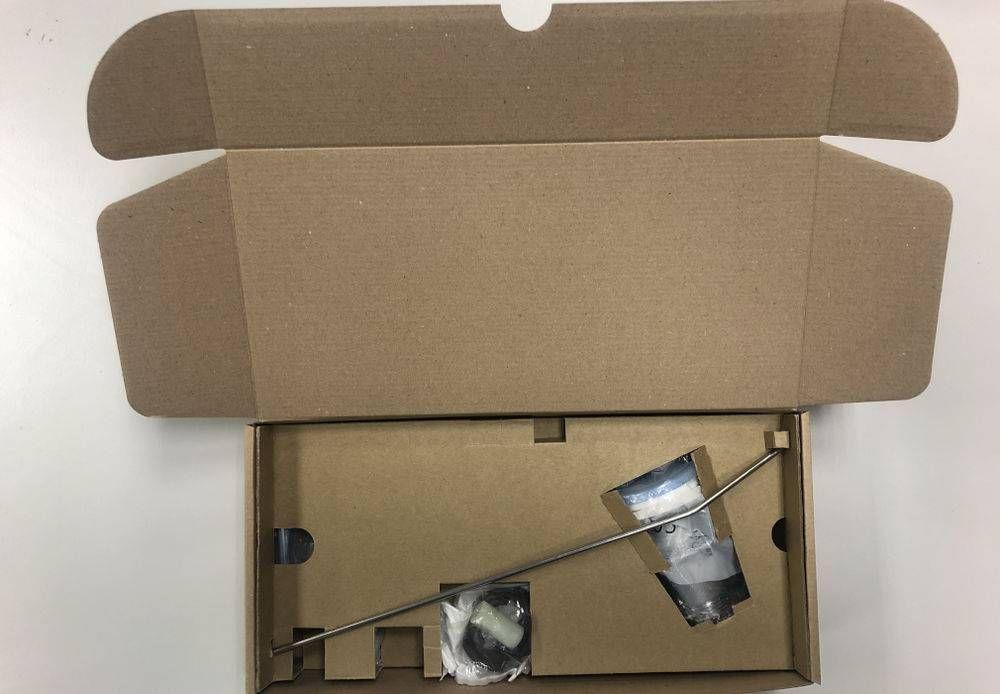

To ensure that everything in the box remains securely in place, each of our products has a special inlay system. A corrugated cardboard inlay provides stable support and ideal protection during transport.

Sustainable packaging concept

Introducing innovative, biodegradable, and recycled materials for a greener future

People, Environment and the Business

By the way, sustainable water use affects more than just the water bill. A lower flow rate generally means less hot water, so less heating energy is used, too. Our thermostats, sendor fitting and the KLUDI EcoPlus feature further enhance the energy efficiency of our products.

Our Philosophy is to go beyond the usual and think regeneratively, ensuring we leave the environment better than we found it.

Designed with innovative water-saving technologies in mind, our products promote responsible water usage for a more sustainable future.

With our ingenious aerator technology, the water is enriched with air and in this way the flow rate of our washbasin and kitchen fittings is reduced to 5 litres or less per minute. So you can #stayfluid in complete relaxation.

With the ingenious flow limitation for showers, the flow rate is reduced to 9 litres per minute. This saves you money for the finer things in life - without having to sacrifice showering comfort.

Water only when you really need it - and your hand movement activates the sensor. This way, less water is wasted and your budget is protected. In addition, the flow rate is reduced as standard. So you save twice.

With KLUDI fittings, you can be sure that the flow values are standards-compliant. We test the fittings’ mechanical wear properties, e.g. the durability of the functional unit (cartridge), using standardised and proprietary test methods. These tests show that high-quality single-lever mixers can easily withstand 210,000 on/off operations and temperature changes. In practice, this is equivalent to roughly 10 years of use.